- Home

-

Products

-

News

News

Keep up to date with new knowledge about testing machines from Zhongtian Measurement and Control.

New services, new products and company news

-

Cases

Cases

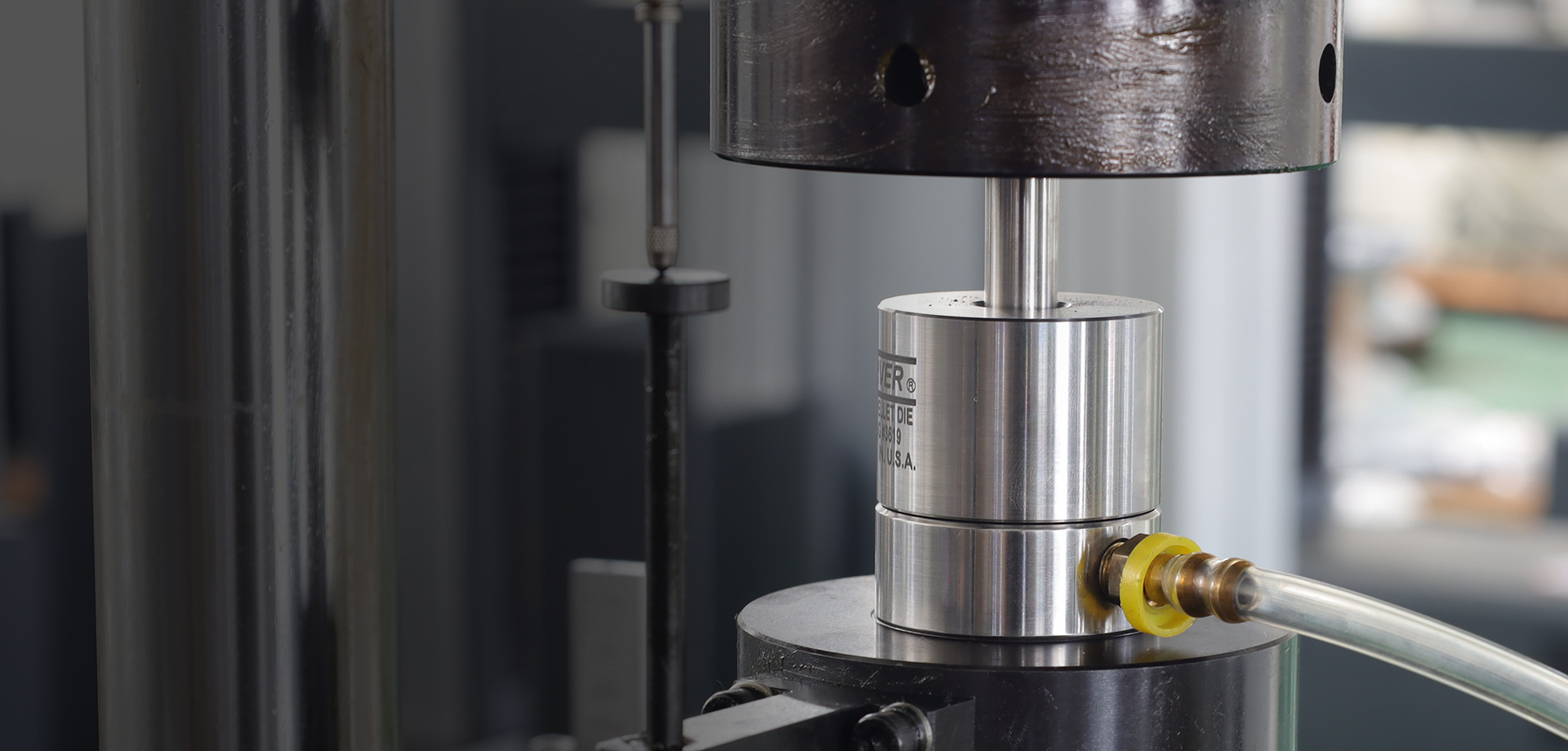

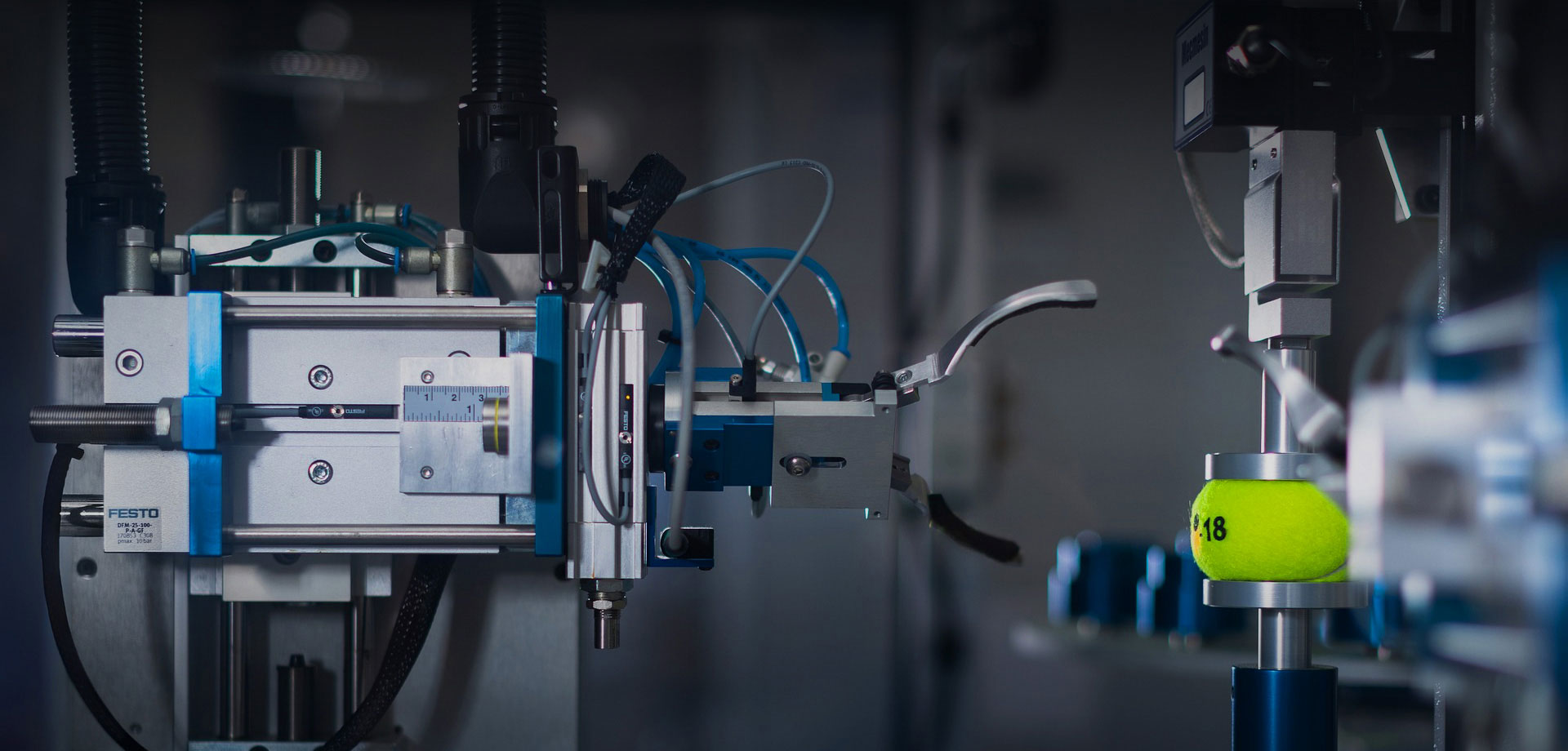

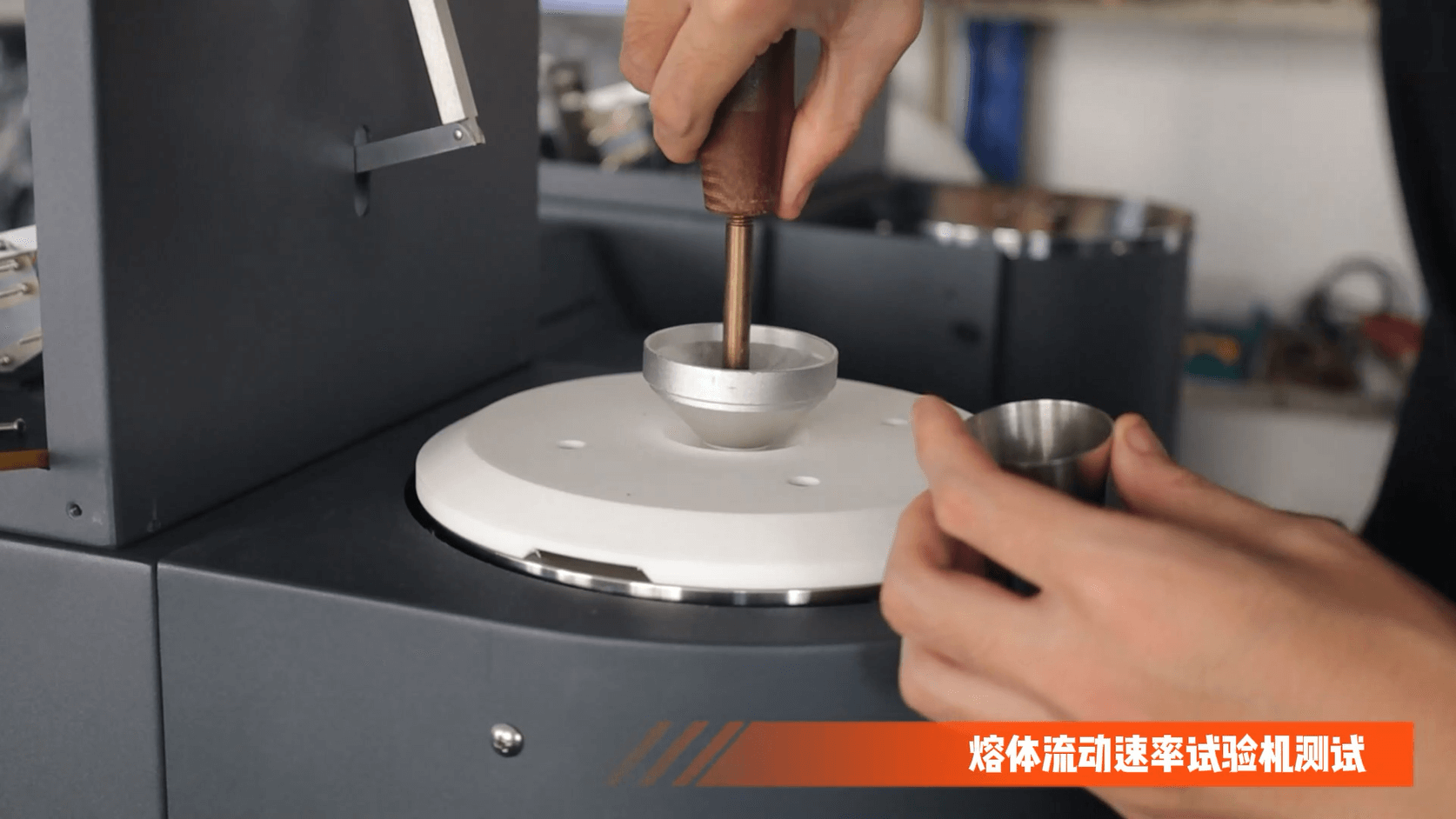

Zhongtian Measurement and Control is a professional manufacturer and seller of mechanical testing machines.

Cooperation cases involve a variety of fields

-

Service Support

Service Support

Zhongtian Measurement and Control provides users with perfect service support for test equipment.

Including pre-sale and after-sale technical support

Data download, product video

-

About Us

About Us

Precise measurement, intelligent control of the future as the core concept

Specialized in providing domestic and foreign customers with high-quality, high-precision testing machines

-

Contact Us

- Home

- Products

-

News

News

Keep up to date with new knowledge about testing machines from Zhongtian Measurement and Control.

New services, new products and company news

-

Cases

Cases

Zhongtian Measurement and Control is a professional manufacturer and seller of mechanical testing machines.

Cooperation cases involve a variety of fields

-

Service Support

Service SupportZhongtian Measurement and Control provides users with perfect service support for test equipment.Including pre-sale and after-sale technical supportData download, product video

-

About Us

About Us

Precise measurement, intelligent control of the future as the core concept

Specialized in providing domestic and foreign customers with high-quality, high-precision testing machines - Contact Us